Cell Therapy

Cell therapy is a rapidly evolving medical field that uses living cells to treat or cure diseases. Scientists aim to harness the unique properties of various cell types to repair or replace damaged tissues, modulate immune responses, and restore normal function. Cellular therapy products include cellular immunotherapies, cancer vaccines, and other autologous and allogeneic cells for specific therapeutic indications, including hematopoietic, adult, or embryonic stem cells. (1)

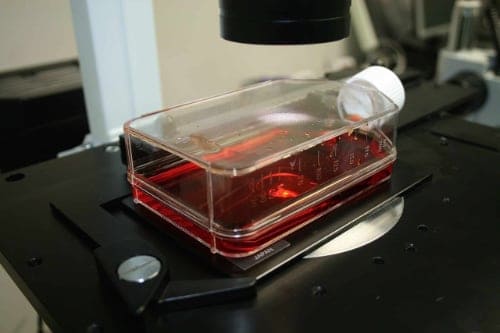

Manufacturing cell therapies involve complex, regulated processes to ensure product safety, efficacy, and consistency. Cell isolation enzymes can play a role in cell isolation and cell expansion. VitaCyte follows guidance on ancillary materials and supports Cell Therapy manufacturers with their regulatory submissions. Ancillary materials, such as cell isolation enzymes, as defined by US Pharmacopeia monograph Chapter <1043> (2) and ISO 20399 (3) that “come into contact with the cellular therapeutic product during cell processing but are not intended to be part of the final product formulation.”

VitaCyte’s Support for Manufacturing Cell Therapeutic Products

VitaCyte addresses three concerns that end-users may have when evaluating different enzyme suppliers to support products used for manufacturing therapeutic cells, as described below.

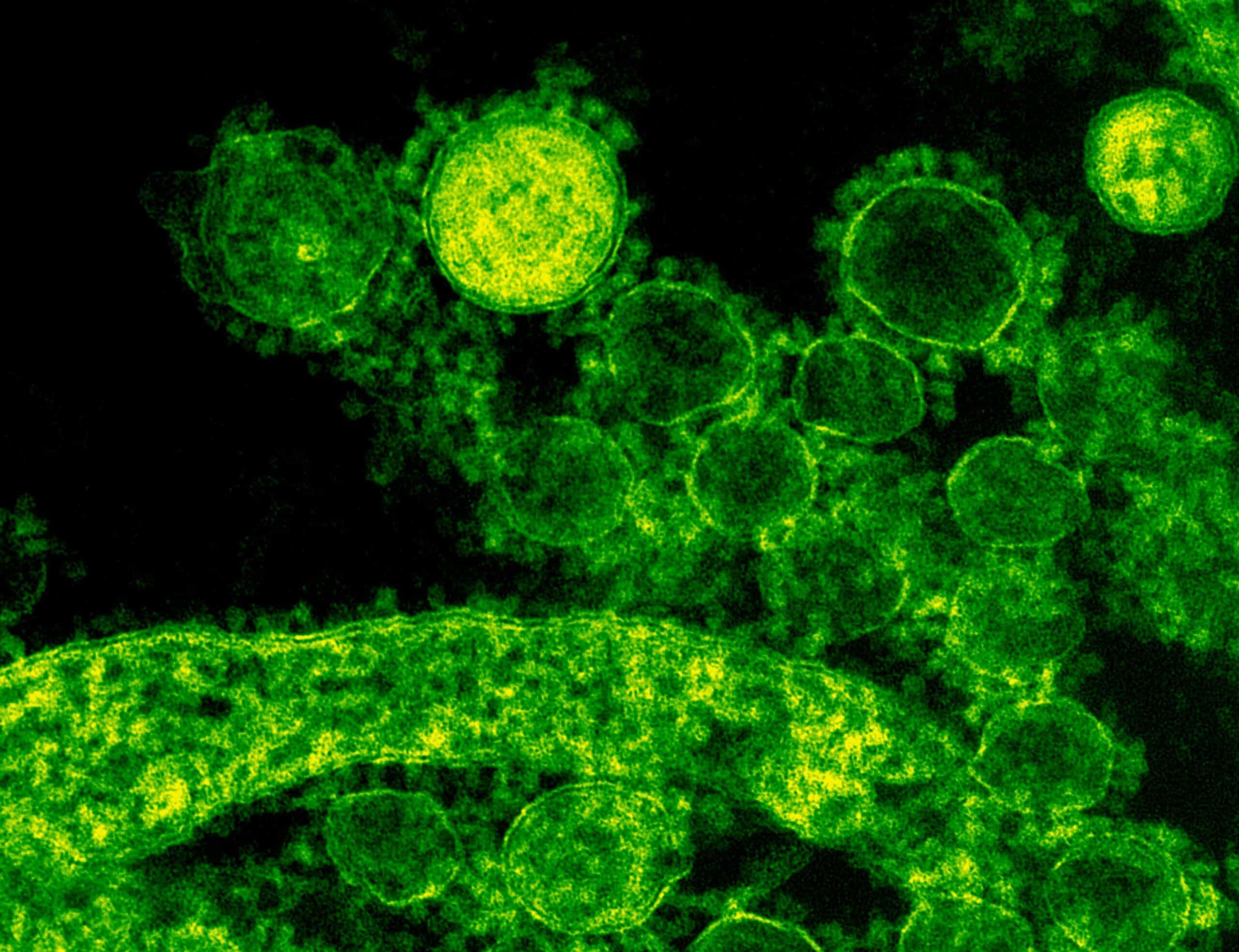

Adventitious Agents

The guidance for adventitious agents emphasizes comprehensive testing and risk mitigation steps throughout the manufacturing process.(4)

VitaCyte’s rCollagenase HI, AM Protease, BP Protease, and Thermolysin are animal-origin-free (AOF) products; they are not generated from or exposed to animal products. The natural, non-recombinant, collagenase and clostripain products are purified from Clostridium histolyticum culture media containing porcine gelatin peptone. The risk for transmission of adventitious agents is mitigated as summarized below:

Fermentation media used to generate histolyticum collagenase raw material uses porcine gelatin peptone; there is no evidence that pigs can be infected with prions, eliminating the risk of transmissible spongiform encephalopathy

No VitaCyte product is exposed to or comes into contact with material of bovine origin

Manufacture of the gelatin peptone product includes multiple high temperature steps known to inactivate many endogenous porcine viruses

The histolyticum fermentation media is steam sterilized at 121°C for 30 minutes, a step that inactivates porcine endogenous viruses

VitaCyte contracted qPCR analysis on selected gelatin peptone lots that showed no porcine or circovirus nucleic acid was in these lots.

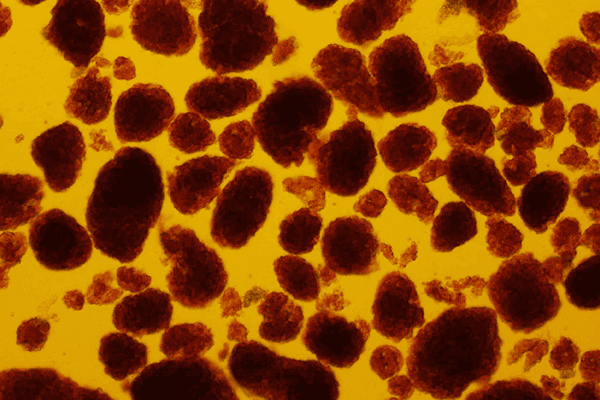

Product Consistency

Enzymes are significant reagents used to recover cells from tissue or cell culture vessels. Enzyme-mediated cell recovery is a critical process parameter that must be tightly controlled. VitaCyte collaborates with end-users to establish specific critical quality attributes (CQAs) impacting the recovery of functional cells. Users should define acceptable ranges of enzyme activities to validate their manufacturing processes.

VitaCyte implements the CQAs through robust column chromatography purification processes and quality control testing to ensure consistent product characteristics across lots. The table below highlights selected features of the collagenase manufacturing and test process.

All purified collagenase products are > 95% pure. The analyses or enzyme activity assays described below assess the GMP-grade collagenase products.

Analytical anion exchange chromatographic analysis for purity and identity including the detection of degraded class I collagenase

Collagenase peptidase activity using FALGPA or Pz-peptide (Wünsch) assays

Collagen degradation activity (CDA) using a fluorescent, kinetic microtiter plate assay and fluorescein isothiocyanate (FITC) conjugated to purified type 1 calf collagen fibrils

Unactivated (i.e., trypsin-like activity) and activated (clostripain) BAEE activity

Endotoxin expressed as EU/A280

Between lot enzyme activity coefficients of variation are typically ≤ 15%. The USP monograph chapter <89.1> and <89.2> for class I and class II C. histolyticum collagenase, respectively, uses analytical anion-exchange chromatography to assess purity and identity.

The kinetic fluorescent microtiter plate assay for measuring collagen degradation activity assesses potency. Collagen degradation activity is the only assay that measures collagenase function.

Nearly all tissue dissociation processes require neutral protease(s) with collagenase to digest tissue. VitaCyte offers several GMP-grade purified neutral proteases that work synergistically with collagenase. A table summarizing the characteristics of VitaCyte’s GMP-grade neutral proteases is shown below. Inter lot assay variability for these products is typically ≤ 15%.

| Thermolysin | BP Protease | AM Protease | Clostripain | |

|---|---|---|---|---|

| Source | Bacillus thermoproteolyticus | Paenibacillus polymyxa | Aspergillus melleus | C. histolyticum |

| Assay Substrate | FITC-HSA | FITC-HSA | FITC-HSA | BAEE Peptide |

| Specific Activity U/mg Protein | 260,000 NP U/mg | 140,000 NP U/mg | 154,000 NP U/mg | 80 BAEE U/mg |

Continuity of Product Supply

VitaCyte ensures a stable supply chain by maintaining a 6- to 9-month raw material reserve. In addition, a robust supplier qualification process provides continuity of raw materials for manufacturing and testing processes.

Additional Information

References

- fda.gov/vaccines-blood-biologics/cellular-gene-therapy-products

- https://www.usp.org/biologics/raw-ancillary-materials

- https://www.iso.org/standard/79399.html

- https://www.fda.gov/media/78428/download

- fda.gov/media/113760/download