Adventitious Agent

Materials of Animal Origin

VitaCyte’s rCollagenase HI, AM Protease, BP Protease, and AF Thermolysin products are entirely animal-origin-free (AOF) products. The only animal sourced material is gelatin peptone derived from porcine skin used in the C. histolyticum collagenase fermentation process. Purified C. histolyticum collagenase is used in Collagenase HA, MA, Collagenase Gold, Gold Plus, CIzyme AS and RI products.

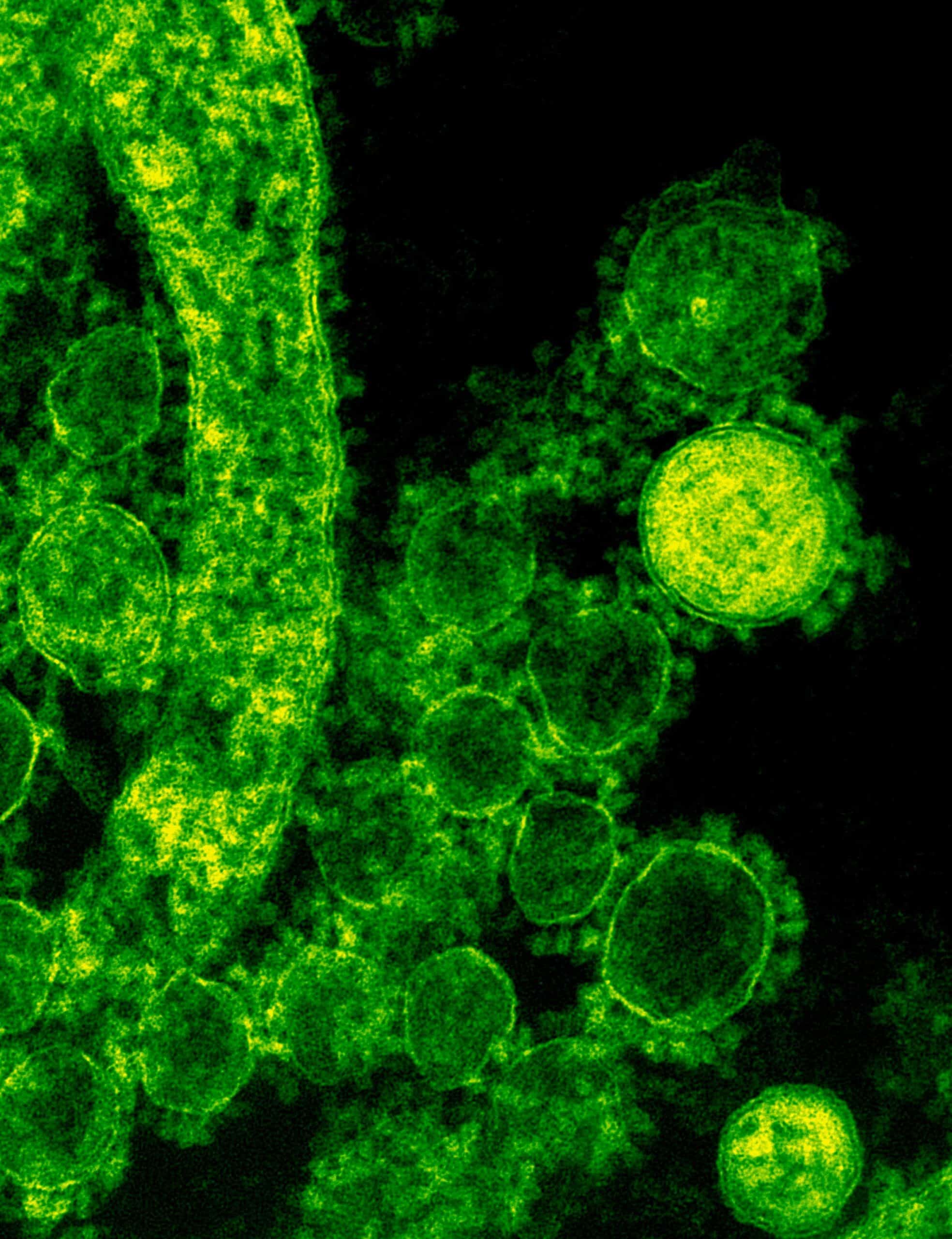

Porcine Viral Risk

Production of purified collagenase products use porcine gelatin peptone in the Clostridium histolyticum fermentation culture media. This animal sourced peptone represents a potential risk of viral adventitious agents when collagenase products are used for therapeutic applications. VitaCyte follows ICH Q5a: Viral Safety Evaluation of Biotechnology Products Derived from Cell Lines of Human or Animal Origin to identify the risks of viral adventitious agents and develop mitigation strategies.(1)

Three key mitigation steps are applied during the manufacturing process to reduce the risk of adventitious agents:

Manufacture of the Gelatin Peptone

The manufacture of the gelatin peptone begins by digesting gelatin with the porcine pancreatin. This process includes multiple steps that are harsh to many viruses of concern including extreme low pH, extreme high pH and several steps performed at high temperatures. The literature suggests these conditions are detrimental to many viruses of concern to the regulatory reviewers as defined in 9CFR §113.47. This process is likely to yield a peptone with little viable viral particles remaining.

Preparation of the Manufacturing Media

The preparation of the media includes an additional heat treatment step in the form of steam sterilization of the gelatin peptone. The prepared culture media is steam sterilized in validated biofermentation equipment. This steam sterilization provides additional risk mitigation measures to inactivate many viruses including those of concern to the FDA as defined in 9CFR §113.47.(1)(2)

Purification of the Collagenase Enzymes

Class I and Class II collagenases (products) are secreted into the culture media during fermentation. At harvest, the cell-free culture supernatant is recovered by passing the culture through a hollow fiber filter and then concentrated using tangential flow filtration (TFF). The recovered retentate undergoes a multi-step column chromatography isolation and purification process that selectively retains the enzymes of interest and allow other contaminants to flow through.

Collectively these three steps represent significant risk reduction measures to eliminate viral adventitious agents from the final product. However, some viruses, particularly parvovirus, are notable for their resilience in the presence of high temperature. For this reason, VitaCyte tested several lots of the porcine gelatin peptone used in the starting media. Test results from a quantitative fluorescent (QF) PCR test found no detectable viral nucleic acid for porcine parvovirus or porcine circovirus 1 & 2 in the samples tested. Since this extremely sensitive QF-PCR testing found no evidence of porcine parvovirus or porcine circovirus nucleic acid in samples of the gelatin peptone starting material, it is acceptable to state these adventitious agents would not be present in the final product as no other animal derived materials are used at any stage of the manufacturing process.

BSE/TSE

None of the components used in the formulation of VitaCyte products use or come into contact with any ingredient of bovine origin during the manufacturing process. The use of porcine derived gelatin represents a minimal risk of Transmissible Spongiform Encephalopathy (TSE). No evidence exists for naturally occurring TSE in pigs or transmission to pigs from infected tissue.

References

- Xu, L., Lee, S. B., Fuchs, C., et. al. (2014) Role of Risk Assessments in Viral Safety: An FDA Perspective PDA J Pharm Sci and Tech. 68; 6-10

- International Federation for Animal Health Europe. (2012) Viral Inactivation Related to Steam Sterilisation of Biological Products.

- Sofer, G, Lister, D, Boose JA. (2003). Virus Inactivation in the 1990s – and into the 21st Century Part 6, Inactivation Methods Grouped by Virus. BioPharm International. 16(4)S-37-42