Quality by Design (QbD)

What is QbD?

The FDA and other regulatory agencies adopted Joseph Juran’s QbD principles to development of drug substances with the key elements directly quoted below from a recent review.

Pharmaceutical QbD is a systemic approach to development that begins with pre-defined objectives and emphasizes product and process understanding and control based on sound science and quality risk management. The goals of pharmaceutical QbD include the following:

- To achieve meaningful product quality specifications that are based on clinical performance

- To increase process capability and reduce product variability and defects by enhancing product and process design, understanding, and control

- To increase product development and manufacturing efficiencies

- To enhance root cause analysis and post approval change management

The key elements of Pharmaceutical QbD are development of:

- Quality target product profiles (QTPP) that identifies the critical quality attributes (CQAs) of the drug product

- Product design and understanding including the identification of critical material attributes (CMAs)

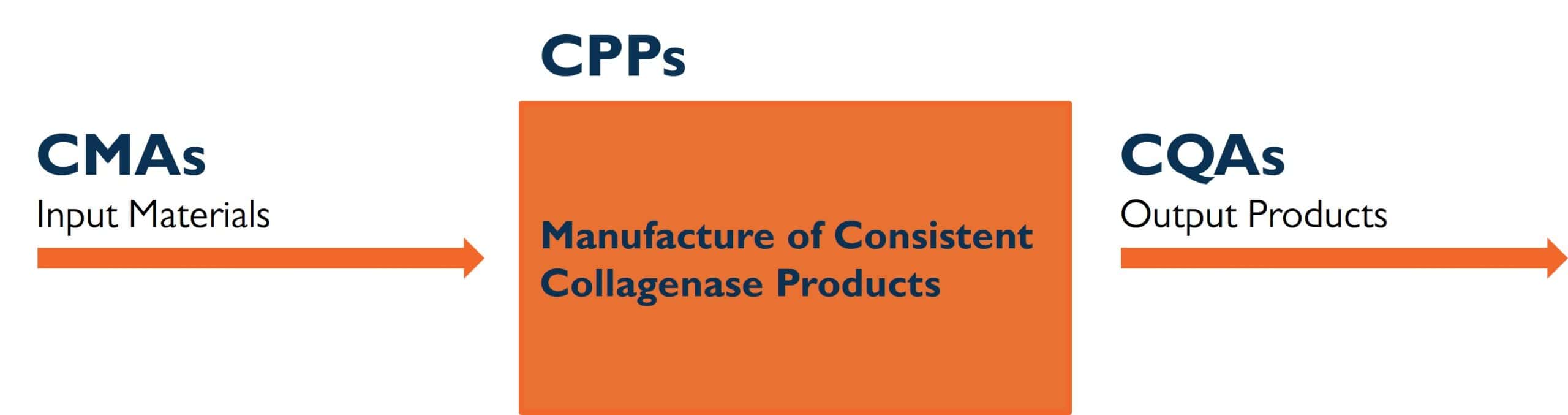

- Process design and understanding including the identification of critical process parameters (CPPs) and a thorough understanding of scale up principles, linking CMAs and CPPs to CQAs.

- A control strategy that includes specifications for the drug substance(s), excipients, and drug product as well as controls for each step of the manufacturing process

- Process capability and continual improvement

VitaCyte’s Application of QbD

VitaCyte applies the principles of Pharmaceutical QbD as framework for manufacturing high purity, rigorously characterized purified-defined Clostridium histolyticum collagenases, both natural and recombinant, as well as neutral proteases. Manufacturing consistent products benefits customers who use these products as research reagents, ancillary materials, or as biotherapeutic drug substances.

This illustration focuses on collagenase but the same QbD principles are applied to all purified enzymes VitaCyte manufactures.

The manufacture of purified-defined collagenase is challenging since if the process is not optimized, collagenase can be degraded resulting in loss of collagen degrading activity, the essential function of this enzyme. The QTPP for VitaCyte’s collagenase products is to manufacture a highly purified enzyme, stable on storage as indicated by preservation of collagen degrading activity.

The relationships between QbD factors are shown in the manufacture of consistent C. histolyticum collagenase products.

The number of steps performed in the purification process and subsequent product characterization is dependent on its final application.

VitaCyte’s CQAs for Purified Collagenase

| CQA Element | Target | Justification |

|---|---|---|

| Collagenase Integrity & Composition | • Define percentage of degraded class I (C1) collagenase as percent of total C1 collagenase • Define C1:class II (C2) ratios | • Intact C1 has the highest specific CDA (CDA U/mg protein) • Minimal degradation of C1 indicates that C2 also intact • Intact C1 and C2 are essential for efficient release of cells from tissue |

| Collagenase Activity | • Specific Collagen Degradation Assay (CDA U/mg protein) using validated assay • Specific Wünsch activity (Wünsch U/mg protein indicates amount of C2 collagenase in product | • CDA evaluates both C1 and C2 activity the essential collagenase activity required for its biological effects • If specific CDA results fail to meet defined parameters, it indicates the enzyme degraded during the manufacturing process |

| Collagenase Purity | • Minimal percentage of clostripain in purified collagenase product • Minimal endotoxin contamination | • Clostripain can degrade C1 collagenase during storage, affecting the specific CDA of the product • Endotoxin is bioactive contaminant |

| Stability | • Minimal 24 month retained activity shelf life when lyophilized product stored at 2 to -30ºC | • Product availability for use |

Application of QbD Principles to the Recovery of Adipose Derived Stromal Vascular Fraction (ADSVF) Cells From Human Lipoaspirate

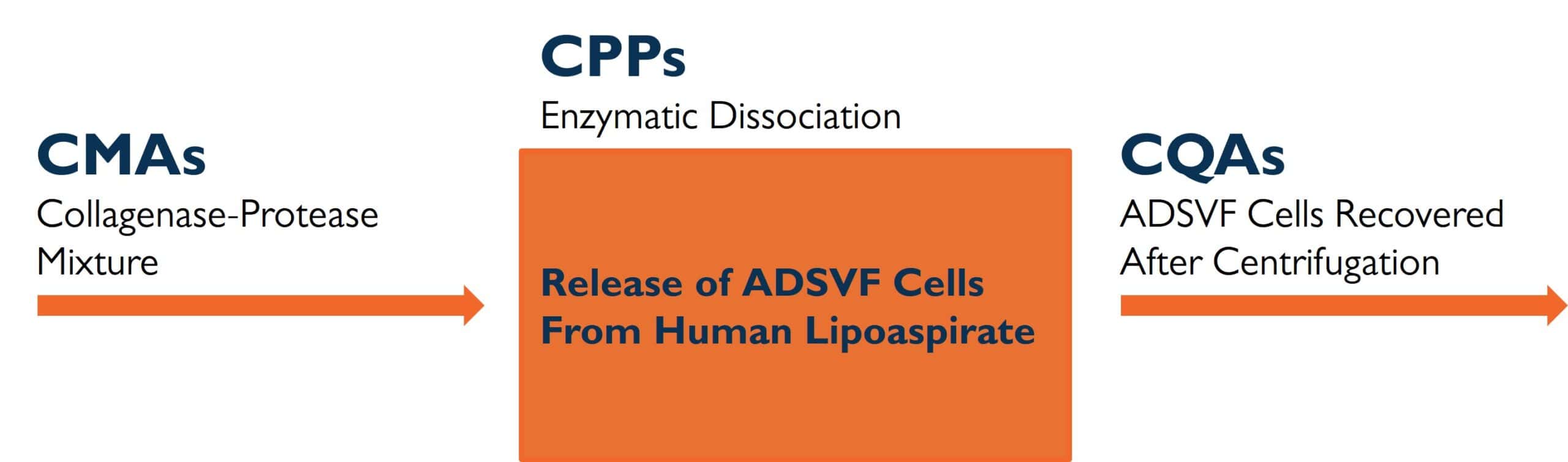

The figure summarizes the CMAs and consequent CQAs of ADSVF cells recovered after collagenase-protease digestion of the lipoaspirate that results in release of ADSVF cells from this material. This example focuses on the enzymes used in the dissociation process. The table shows how the CMAs correlate with the CQAs in the ADSVF cells recovered after centrifugation.

| CMA | CQA | Linkage of CMA to CQA |

|---|---|---|

| CDA and NPA (neutral protease activity) used in the enzyme solution to digest human lipoaspirate | • Cell viability • Viable cell yield per mL of lipoaspirate • % CD 45 to estimate leukoctyes • % CD 29, 31 and 34 to confirm presence of markers consistent with ADSVF cells | • Both enzyme activities impact cell viability and yield • NPA impacts speed of digestion, cell viability, and damage to CD membrane markers • A supraoptimal dose of protease will likely decrease cell viability, lowering cell yield • High protease will degrade membrane CD markers, impacting estimate of cell populations |

| Endotoxin Contamination | • Level of endotoxin | • FDA concerned with endotoxin contamination in cellular products, minimize exogeneous contribution to this biologically active contaminant |